What You Should Know About The Bell & Gossett Series 1510 Pump

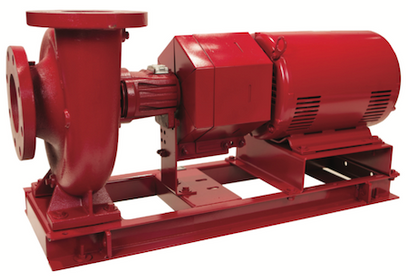

There are several centrifugal pumps available out there but what makes The Bell & Gossett Series 1510 Pump unique? While there are many factors considered to rate a pump, this one truly stands strong across features and benefits to the user. This article intends to bring out the same in order to help make pump purchasers an informed decision.

The base mounted Bell & Gossett Series 1510 Pump series is available in sizes 1-1/4" through 8", 1/2 HP - 150 HP at 1750 RPM; 2 HP - 150 HP at 3500 RPM. It is highly flexible and competitively priced.

Here are the stunning features:

True Back Pullout

Coming with a back pullout design, the Bell & Gossett Series 1510 Pump is made easy on maintenance. The design ensures the motor and piping remain undisturbed and stay in place. The design also allows for quick and easy repairs; this means you can get your pump fixed in minimum time.

Self-flushing internal mechanical seal

The contemporary design has made possible internal self flushing, without the need for any external provisions for the same. This feature also allows for seal face lubrication, debris removal and heat dissipation with ease.

Automated Impeller Balancing

Computer balanced impellers have made possible vibration free, quiet and efficient performance, making the users highly satisfied. Diameters are system selected at the works. Finally, your capacity requirements will be adhered to. Impellers are balanced to ANSI/HI 9.6.4-2009 Hydraulic Institute Standards with a grading of G6.3. The vibration limits also align with the standards.

Heavy duty BasePlate

Each Bell & Gossett Series 1510 Pump comes with a heavy duty baseplate. It has an open top, seam welds, a strong saddle assembly and closed ends. The design of this rugged baseplate is simple yet high on utility, making it entirely different from and superior to the typical baseplates available with the other ordinary pumps.

Solid- foot mounted volute

There's this volute foot provided with Bell & Gossett Series 1510 Pump that is located right under the volute. This ensures grip and makes sure there is proper alignment between the motor assembly and volute. The strong support avoids distortion and ensures longevity of the shaft, bearings and the mechanical seal.

While normally there are deflections found with the thermal expansion, with this pump, they are completely eliminated.

Center drop-out spacer coupling

This is in total contrast with the traditional jaw coupling. There's a dropout spacer coupling in the center that makes removing of the bearing frame easy. This way, there is no disturbance caused either to the motor electrical connections or the pump end pipe alignment.

ANSI/OSHA compliant guard

The coupling guard adheres to ANSI B15.1 and OSHA 1910.219. The guard also secures against possible injuries and come with openings for inspection.

Patented condition monitor

The monitor measures the temperature and vibration constantly and immediately indicates whenever these levels are exceeded. This enhances the performance of the Bell & Gossett Series 1510 Pump; at the same time reduce life cycle costs. It is efficient and always provides accurate readings.

Construction

- All the parts are of standard make and assure durability. Stainless steel, cast iron and cast bronze are the prominent materials used for constructing Bell & Gossett Series 1510 Pumps.

- There are bronze fitted pumps and all-iron pumps available; the make and configuration depends on which kind of pump you choose.

- Each pump is manufactured in accordance with ISO 9001 standards and hydrostatically tested. It is cleaned and painted to create an appealing look before the shipment.

Are you ready to buy one? Give us a call today. Please note the B&G series 1510 pump has now been replaced by the new e-series pump. Please see this link for more information on the Bell & Gossett Series e-1510 Centrifugal Pumps.

Recent Posts

-

The Bell & Gossett Ecocirc XL Pump

The Bell & Gossett Ecocirc XL Pump: Innovation in Efficiency and ReliabilityIntroductionIn the w …18th Jul 2024 -

The Efficiency of The Bell & Gossett Series e-1510 Centrifugal Pump

Bell & Gossett Series e-1510 centrifugal pumps are one of the most efficient pumps in the market …22nd Mar 2023 -

How Important Is The Bell & Gossett Expansion Tank

Bell & Gossett expansion tanks are an important component in any hydronic heating or cooling system. …20th Feb 2023